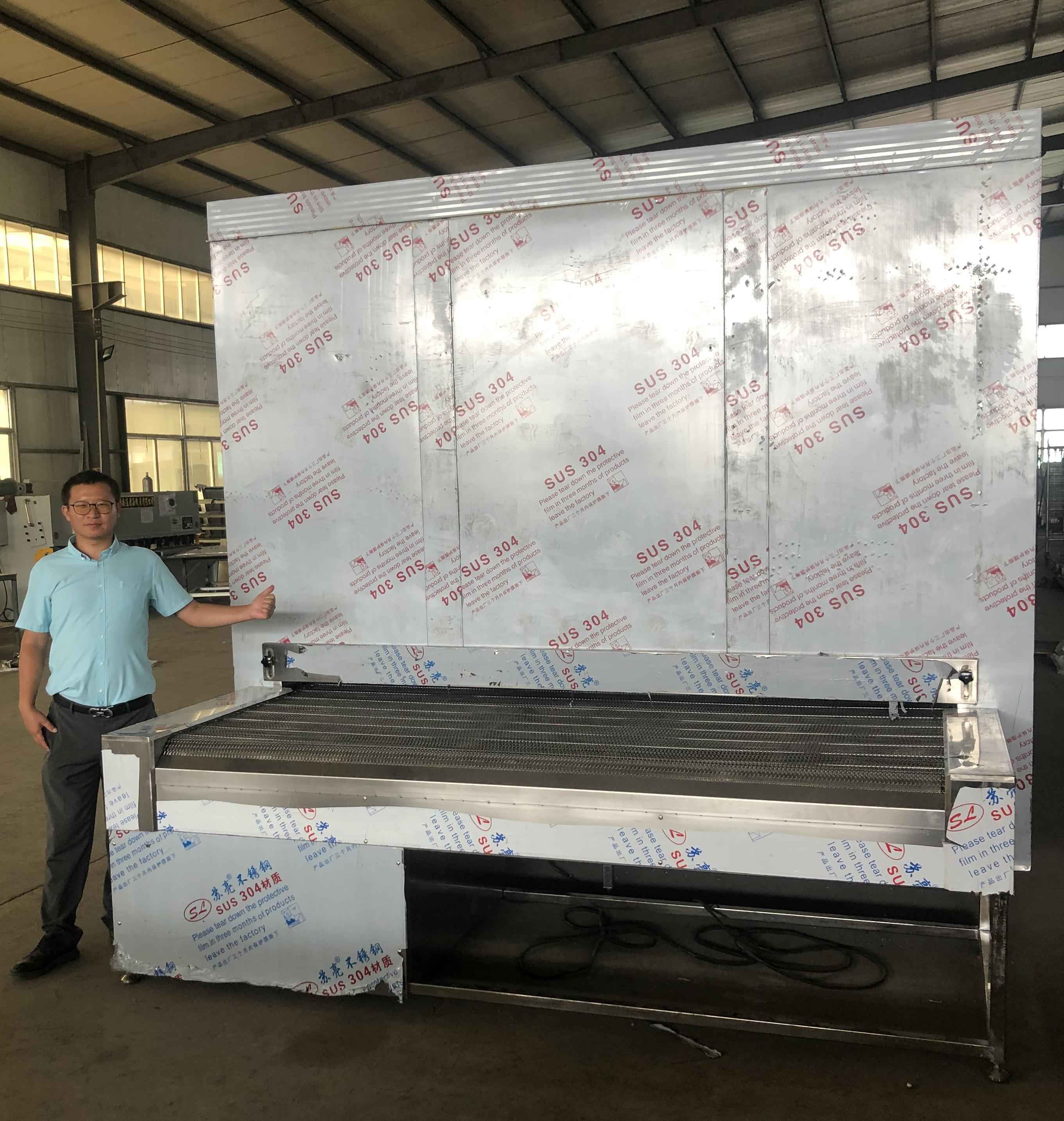

500kg/h IQF tunnel freezer exprot Tajikistan

Tunnel Freezer Exported to Tajikistan for Freezing Chicken Thighs

Tunnel Freezer Customized to Meet Customer's Non-standard Requirements, with a Production Capacity of 500kg/h

Tunnel freezer Introduction: The global food industry is constantly evolving, driven by the demand for innovative and efficient processing equipment. In this regard, the tunnel freezer has emerged as a vital tool for freezing various food products, including chicken thighs. This article highlights the successful export of a tunnel freezer to Tajikistan, specifically designed to meet the non-standard requirements of a customer looking to freeze chicken thighs.

The Importance of Tunnel Freezers in the Food Industry: Tunnel freezers are widely recognized for their ability to rapidly freeze food products, preserving their quality, taste, and nutritional value. These machines utilize a continuous conveyor belt system, enabling a consistent and efficient freezing process. The rapid freezing of food products is crucial in maintaining their freshness, extending shelf life, and preventing the growth of harmful bacteria.

Customization to Meet Customer's Requirements: In the case of the tunnel freezer exported to Tajikistan, the customer had specific requirements for freezing chicken thighs. Understanding the importance of tailoring equipment to meet customer needs, the manufacturer engaged in non-standard customization to ensure optimal performance and efficiency.

Production Capacity and Output: The tunnel freezer was designed to handle a production capacity of 500kg/h, allowing for a high volume of chicken thighs to be frozen within a given time frame. This capacity ensures that the customer can meet the demands of their market, while also maintaining a streamlined production process.

Advanced Features and Technology: To achieve the desired freezing results, the tunnel freezer incorporated advanced features and technology. These included precise temperature control mechanisms, adjustable conveyor speeds, and efficient air circulation systems.

Such features are essential in maintaining consistent freezing conditions and ensuring uniform freezing of the chicken thighs.

Quality Assurance and Compliance: The manufacturing process of the tunnel freezer adhered to strict quality standards and regulations. The equipment was tested thoroughly to ensure its reliability, durability, and compliance with international food safety standards. This commitment to quality guarantees that the frozen chicken thighs meet the highest standards of hygiene and safety.

The successful export of a tunnel freezer to Tajikistan for freezing chicken thighs showcases the importance of customization and innovation in the food processing industry. By understanding and meeting the specific requirements of customers, manufacturers can provide tailored solutions that enhance productivity and quality. The tunnel freezer's ability to freeze chicken thighs at a production capacity of 500kg/h, coupled with its advanced features and compliance with quality standards, ensures that the customer can meet market demands while delivering safe and high-quality frozen products.