Applications and Services

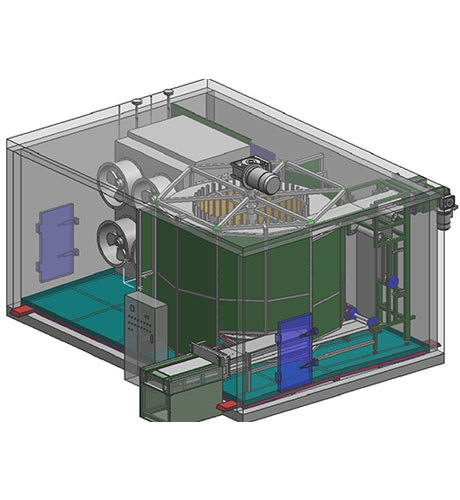

Fluidized bed IQF Freezer

Freezing Capacity:300kg/h-8000kg/h

Products:Fruits, vegetables, french fries, and seafood

Features:Individual quick freezing (IQF) is a technology developed as a specific solution to block or cluster-freezing of small-sized products, to preserve quality and to give unparalleled convenience to end-users. The IQF freezer covers a broad range of product types such as fruits, vegetables, diced meat, shrimp,etc.

This IQF freezer is designed based on our more than 15 years of experience in IQF freezing and manufacturing. Our freezer uses the fluidizing principle by directing frigid air upward through the stainless steel mesh belt to fluidize the product. Fluidization means that we make the mass of food particles behave like a liquid. This technique provides high heat transfer between the air and the product and keeps the product in motion during freezing. Therefore, our freezer will have a true individual quick freezing (IQF) of the products.

Benefits:

More than 15 years experience in the IQF freezer manufacture filed.

More than 15 years experience in the IQF freezer manufacture filed. Pre-assembled and fully tested at our factory.

Pre-assembled and fully tested at our factory. Easily installed on site.

Easily installed on site. Built to CE ;ISO9001 Specifications & international Standards

Built to CE ;ISO9001 Specifications & international Standards Saving in processing floor space and personal costs.

Saving in processing floor space and personal costs. Easy access to sanitation and maintenance.

Easy access to sanitation and maintenance. Custom designs available

Custom designs available

Structure:

All structures are made of 304 stainless steel and UHMWP engineering plastic, Sloped floor, and elevated floor-enclosure joint to guarantee hygiene standardLibrary board adopts double stainless steel self-extinguishing flame retardant polyurethane sandwich insulation board, panel thickness 0.8 mmSUS304 stainless steel plate, the plate thickness 150mm Thermal insulation material, the plate adopts self-extinguishing flame retardant rigid polyurethane meet the following indicators: 40 kg/m3 density requirements or greater (less than a full board average density, then cutting sampling density); Coefficient of thermal conductivity is 0.024 w/m.k or less; Requirement: the compressive strength of the wall panel, roof is 150 ~ 200 Kpa, ground 300 Kpa or higher; Bibulous rate is 4% or less; Dimensional stability < 1% (30 ℃, 48 h); Self-extinguishing 7 seconds or less.

Two stage or one stage belting structure with independent speed control, providing perfect IQF results with true fluidization.

Conveyor belt, chain network USES the food grade bright spring SUS304 stainless steel, with smooth surface, plate, wear shaft connected with flexible operation, large roller transmission chain net rolling;

- 2

Mesh belt and guide slide friction in contact area using high molecular wear-resisting PVC materials. Make guide slide friction is more reliable when in contact with the mesh belt and separation, not to drop crumbs, ensure the security of the frozen goods.

- 3

Inlet platform fortification material ultra-high transfinite device, adjustable stainless steel wind insulation device; discharging mouth platform set up automatic blanking.

- 4

The transmit driver using frequency conversion speed reducer, mesh belt running frequency control of motor speed, frozen time adjusted. Aluminum evaporator with variable fin spacing. High heat removal capacity. Easy to clean.

- 5

Controlled Airflow to make freezing products suspend above the conveyor belt.PLC control system, variable belt-running speed control.Modular design with minimal internal structure and framework, easy to maintain and clean.

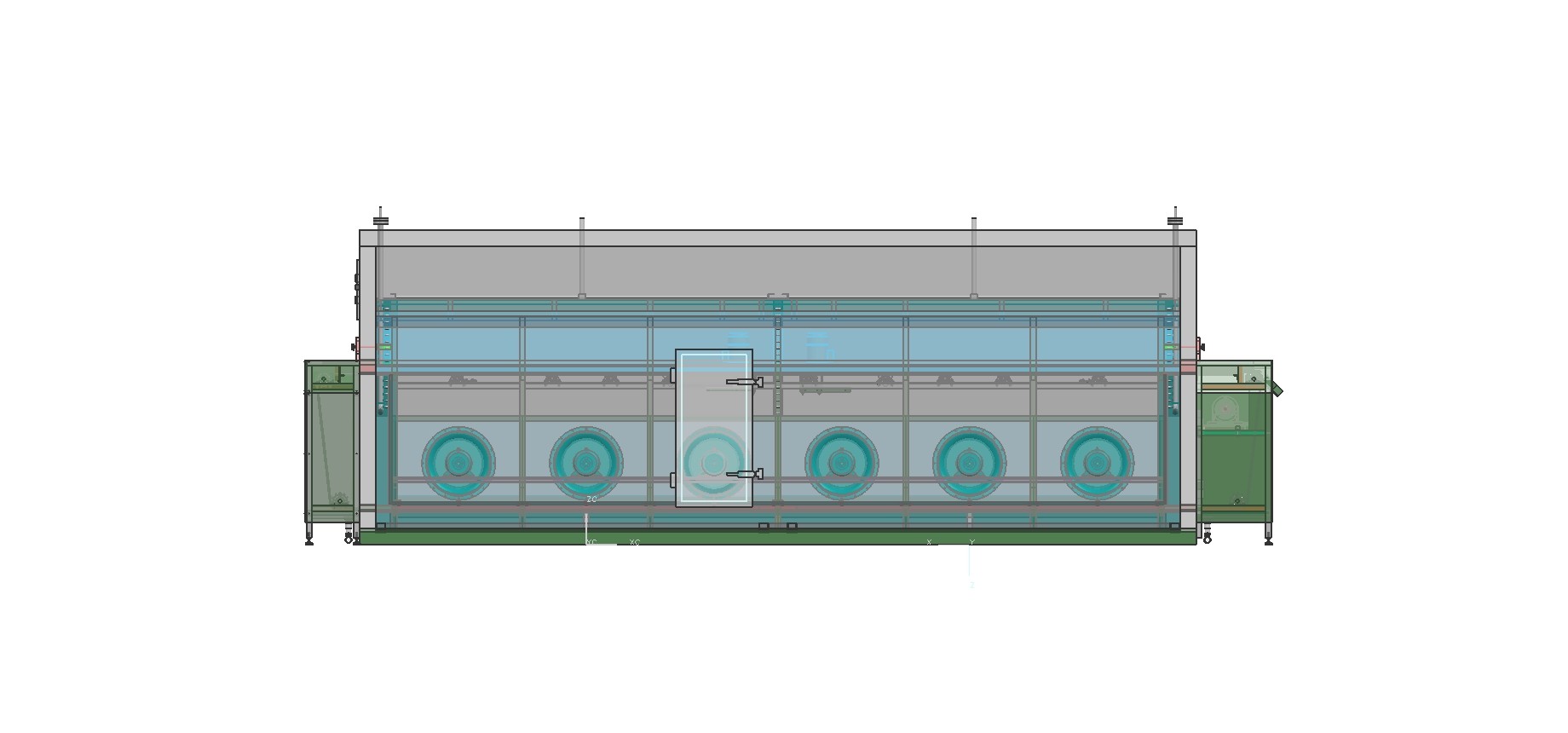

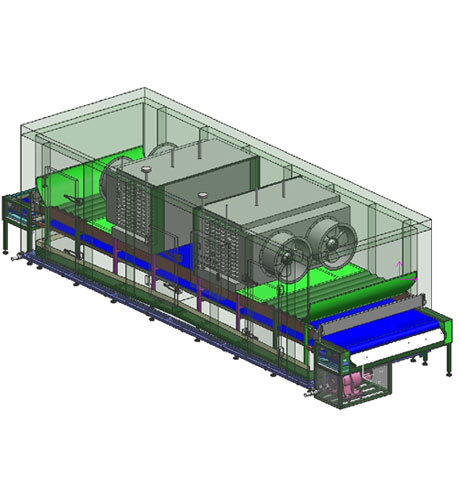

Tunnel Freezer

Freezing Capacity:50-2,000 kg/hr

Products:The Tunnel Freezer is designed to freeze a wide variety of wet and soft products such as raw meat, meat patties, shrimp, squid, fish, fillets, buns, poultry, prepared food, bulky food.etc

Features:

Consists of: Stainless steel band, aluminum air units (evaporators), insulated enclosure, control panel and supporting frames. It is completely assembled and pre-wired in modular sections, for easy installation and for future expansion in freezing capacity. Both the mesh belt and band belt tunnel freezers are easy to operate, require the least maintenance, and have the lowest operation cost of any of our freezers.

The product is loaded manually or by spreader shaker on to the stainless steel band belt from one end, then the product travels in to the tunnel sections, where the high velocity air blasts horizontally across the top of product surface and under the belt. The horizontal air direction alternates from one section to the next so as to achieve even freezing. Upon exiting the tunnel sections the frozen product releases off the belt smoothly without marks. The product shall be frozen in same form as it was loaded on the inlet end.

Benefits:

Pre-assembled and fully tested at our factory.

Pre-assembled and fully tested at our factory. Easily installed on site.

Easily installed on site. Built to CE ;ISO9001 HACCP Specifications & international Standards

Built to CE ;ISO9001 HACCP Specifications & international Standards Saving in processing floor space.

Saving in processing floor space. Easy access to sanitation and maintenance.

Easy access to sanitation and maintenance. Custom designs available

Custom designs available

Structure:

Tunnel type freezer mainly by the transmission part, evaporator, PU and electrical equipment The net belt with a large stick chain transmission, reduce mechanical friction, running the use of rectangular square tube + ultra-high wear resistance. The structure of the freezer inside is made of stainless steel, water defrosting series device, the transmission shaft is usually stainless steel shaft, clean and sanitary, the equipment is reliable, long service life, the belt can be ventilated up and down, the freezing speed is fast. Evaporator: the evaporator is made of stainless steel or copper or aluminum tube and aluminum fins, with variable sheet spacing to ensure smooth wind circulation.high heat transfer efficiency, quick freeze (cooling )fast, evaporator along the belt with the direction of running ,Wind area is large, therefore not easy to frost, can be a long time continuous production.

One belt runs independently ,According to customer requirements, it can provide double belt design to meet customers' needs of freezing different products at the same time.

- 1

Evaporator: the evaporator is made of stainless steel or copper or aluminum tube and aluminum fins, with variable sheet spacing to ensure smooth wind circulation.high heat transfer efficiency, quick freeze (cooling )fast, evaporator along the belt with the direction of running ,Wind area is large, therefore not easy to frost, can be a long time continuous production.

- 2

PU: insulation with double-sided stainless steel polyurethane 150mm insulation board body board, insulation effect is good, PU door for the double-sealed and with electric heating, effectively prevent freezing.

- 3

Thermal insulation material: the plate adopts self-extinguishing flame retardant rigid polyurethane meet the following indicators: 40 kg/m3 density requirements or greater (less than a full board average density, then cutting sampling density); Coefficient of thermal conductivity is 0.024 w/m.k or less; Requirement: the compressive strength of the wall panel, roof is 150 ~ 200 Kpa, ground 300 Kpa or higher;Bibulous rate is 4% or less; Dimensional stability < 1% (30 ℃, 48 h); Self-extinguishing 7 seconds or less.

- 4

Electrical system: the use of stainless steel control cabinet, electrical components are used well-know brands, beautiful appearance, easy to operate. According to customer requirements using PLC control.

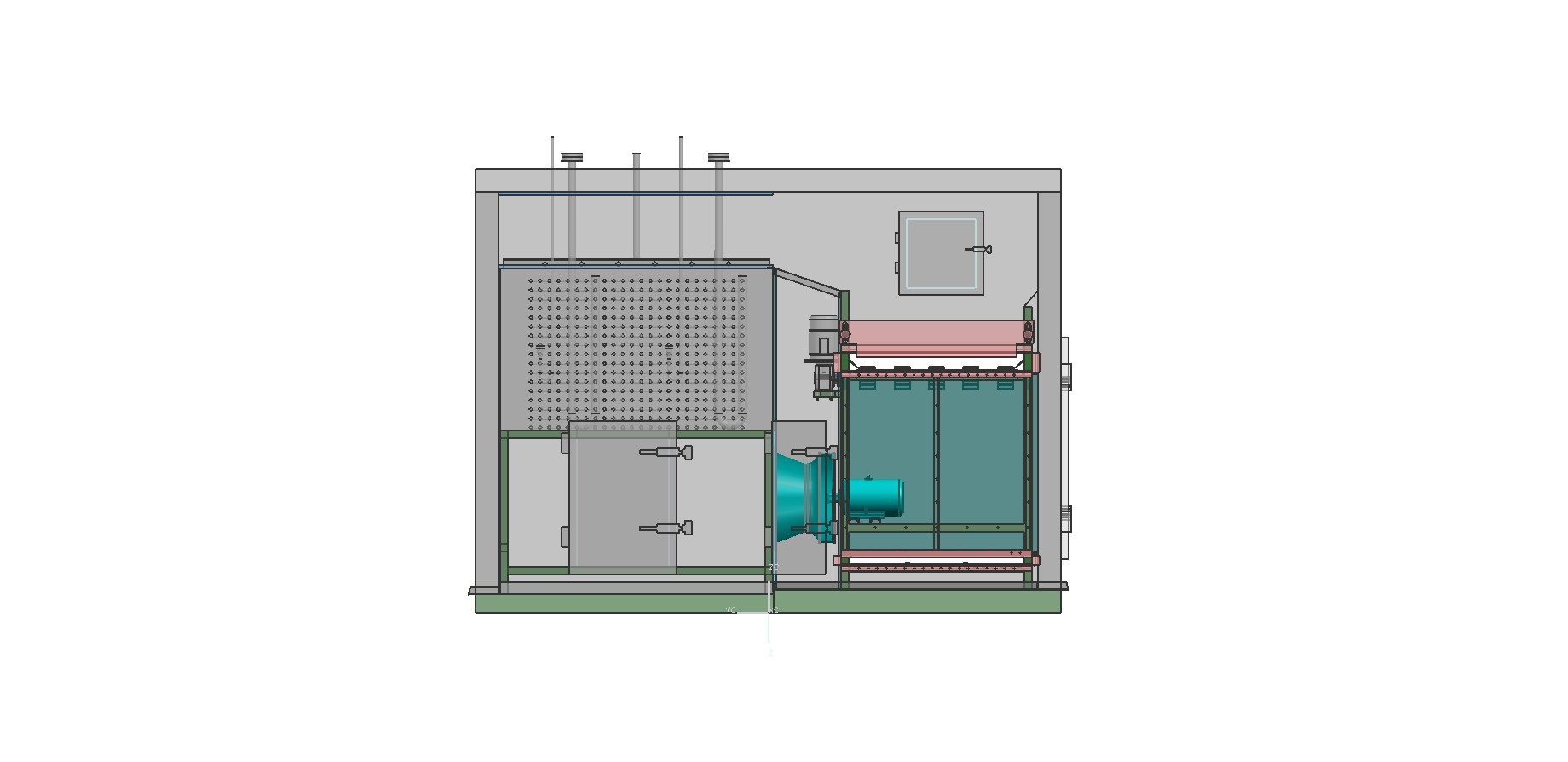

Single drum spiral freezer

Freezing Capacity Range:200kg-8000kg/hr

Products:Poultry, meat patties, raw shrimp, fish fillets, scallops, whole fish, packaged food in trays, ice cream cups, products requiring a long retention time.

Features:The freezer is a continuous in-line-belt freezer designed to minimize product weight loss and assure quality with gentle handling during the freezing process. Products are evenly fed from the production line directly onto the loading freezer belt. It quickly transports the product into the low temperature-freezing zone.

The belt spirals up or down along the rotating drum until it reaches the top or bottom where the frozen product is gently discharged from the freezer discharge port. Due to the large belt surface available, products can be frozen in single layers or individually for IQF (Individually Quick Frozen) quality. Because products can maintain their original load-in position throughout the freezing process, sorting after simultaneous freezing of mixed, different products is simplified.

Benefits:

All seamless welded stainless steel enclosure with robust welded steel support structure.

Customized airflow for efficient heat transfer

Pre-Assembled and fully tested at our factory before shipping.

Pre-Assembled and fully tested at our factory before shipping. Built to CE IS09001 HACCP Specifications & Standards

Built to CE IS09001 HACCP Specifications & Standards Continuous inline food freezing.

Continuous inline food freezing. Gentle smooth handling of products.

Gentle smooth handling of products. Compact design lowers operation cost and saves process floor space.

Compact design lowers operation cost and saves process floor space. High efficiency allows fast freezing.

High efficiency allows fast freezing. High efficiency allows fast freezing.

High efficiency allows fast freezing. Minimum product weight loss by exposure to lowest air temperature at all times.

Minimum product weight loss by exposure to lowest air temperature at all times. Stainless steel construction.

Stainless steel construction. Easy access to sanitation and maintenance from all sides.

Easy access to sanitation and maintenance from all sides. Custom designs to fit your requirements

Custom designs to fit your requirements Compact drive device is durable, safe and low in maintenance.

Compact drive device is durable, safe and low in maintenance.

Structure:

The Spiral freezer is mainly by transmission part, evaporator, PU and electrical apparatus.The transmission part is consists of transmission motor, net belt, drum and independent frequency converter. The evaporator is composed of stainless steel and aluminum fins, with variable sheet spacing to ensure smooth wind circulation. The evaporator pipe can be aluminum tube, copper tube and stainless steel tube; The PU is made of stainless steel + Polyurethane insulation Thermal insulation material, the plate adopts self-extinguishing flame retardant rigid polyurethane meet the following indicators: 40 kg/m3 density requirements or greater (less than a full board average density, then cutting sampling density); Coefficient of thermal conductivity is 0.024 w/m.k or less; Requirement: the compressive strength of the wall panel, roof is 150 ~ 200 Kpa, ground 300 Kpa or higher; Bibulous rate is 4% or less; Dimensional stability < 1% (30 ℃, 48 h); Self-extinguishing 7 seconds or less. The electrical system is composed of stainless steel and well-know electrical components and PLC

According to customer requirements, provide single spiral and double spiral freezer design。

- 1

High freezing capacity and more automation;

- 2

Compact structure and Saving floor occupying;

- 3

Transmission belt, with strong resistance to elongation and high abrasion resistance, thus improving the service life and stability of the equipment;

- 4

The equipment is equipped with a network belt to run the self-inspection device, which can monitor the network operation status at any time and eliminate unnecessary losses caused by the operation of the network belt.

- 5

With Outside transmission system , the equipment, reliable operation, energy saving, easy maintenance, in line with HACCP requirements.

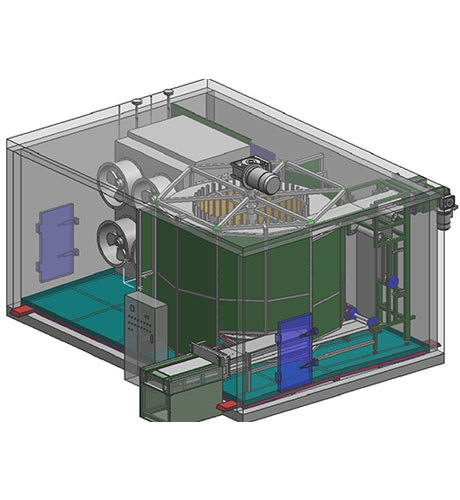

Double spiral freezer

Freezing Capacity Range: 1000kg-4000kg/hr

Products: Poultry, meat patties, raw shrimp, fish fillets, scallops, whole fish, packaged food in trays, ice cream cups, products requiring a long retention time.

Key Features: The Twin Drum Spiral freezer is designed to freeze a large quantity of products in less space, especially for products needing long freezing time such as bulky foods, or raw poultry and meat. We can customize the freezing process to meet your various demands. The twin drum freezer is an ideal solution for mass production process.

The belt spirals up or down along the rotating drum until it reaches the top or bottom where the frozen product is gently discharged from the freezer discharge port. Due to the large belt surface available, products can be frozen in single layers or individually for IQF (Individually Quick Frozen) quality. Because products can maintain their original load-in position throughout the freezing process, sorting after simultaneous freezing of mixed, different products is simplified.

Benefits:

All seamless welded stainless steel enclosure with robust welded steel support structure.

Customized airflow for efficient heat transfer

Pre-assembled and fully tested at our factory before shipping.

Pre-assembled and fully tested at our factory before shipping. Ready to be placed and connected to refrigeration, electrical and water service.

Ready to be placed and connected to refrigeration, electrical and water service. Built to CE ISO9001 HACCP Specifications & Standards

Built to CE ISO9001 HACCP Specifications & Standards Continuous inline food freezing.

Continuous inline food freezing. Gentle, smooth handling of products.

Gentle, smooth handling of products. Minimum product weight loss by exposure to lowest air temperature at all times.

Minimum product weight loss by exposure to lowest air temperature at all times. Stainless steel construction.

Stainless steel construction. Easy access to sanitation and maintenance from all sides

Easy access to sanitation and maintenance from all sides Multifunctional PLC system.

Multifunctional PLC system. Stainless steel rails are covered with a UHMW polyethylene wear strip for many years of smooth and maintenance-free operation

Stainless steel rails are covered with a UHMW polyethylene wear strip for many years of smooth and maintenance-free operation Modular Design for easy and quick on-site installation.

Modular Design for easy and quick on-site installation. Custom designs to fit your requirements

Custom designs to fit your requirements

Structure:

The Spiral freezer is mainly by transmission part, evaporator, PU and electrical apparatus.The transmission part is consists of transmission motor, net belt, drum and independent frequency converter. The evaporator is composed of stainless steel and aluminum fins, with variable sheet spacing to ensure smooth wind circulation. The evaporator pipe can be aluminum tube, copper tube and stainless steel tube; The PU is made of stainless steel + Polyurethane insulation Thermal insulation material, the plate adopts self-extinguishing flame retardant rigid polyurethane meet the following indicators: 40 kg/m3 density requirements or greater (less than a full board average density, then cutting sampling density); Coefficient of thermal conductivity is 0.024 w/m.k or less; Requirement: the compressive strength of the wall panel, roof is 150 ~ 200 Kpa, ground 300 Kpa or higher; Bibulous rate is 4% or less; Dimensional stability < 1% (30 ℃, 48 h); Self-extinguishing 7 seconds or less. The electrical system is composed of stainless steel and well-know electrical components and PLC

According to customer requirements, provide single spiral and double spiral freezer design。

- 1

High freezing capacity and more automation;

- 2

Compact structure and Saving floor occupying;

- 3

Transmission belt, with strong resistance to elongation and high abrasion resistance, thus improving the service life and stability of the equipment;

- 4

The equipment is equipped with a network belt to run the self-inspection device, which can monitor the network operation status at any time and eliminate unnecessary losses caused by the operation of the network belt.

- 5

With Outside transmission system , the equipment, reliable operation, energy saving, easy maintenance, in line with HACCP requirements.

Air blast freezer

Products:Fish, fruits, vegetables and a variety of other irregularly shaped products.

Features:The big advantage of the blast freezer is its versatility - it can cope with a variety of irregularly shaped products. Wherever there is a wide range of shapes and sizes to be frozen, the blast freezer is the better choice.

Dual modes of Air blast and direct contact guarantee fast freezing. Electric energy vibrates the water molecules inside the freezer, preventing the formation of ice crystals inside the cells. This protects the cell walls from damage, and lessens drip when defrosting. A layer of ice quickly covers the surface of the food, preventing cell moisture from escaping and eliminating frost. The fan air speed changes automatically, preventing surface drying.

Benefits:

Freezer is made of 304 stainless steel, which ensures high hygiene standards and low maintenance

Freezer is made of 304 stainless steel, which ensures high hygiene standards and low maintenance Dual freezing methods: Air blast and direct contact, provide optimal freezing effects.

Dual freezing methods: Air blast and direct contact, provide optimal freezing effects. Enclosure is made of 304 stainless steel and is insulated to guarantee best cold retention.

Enclosure is made of 304 stainless steel and is insulated to guarantee best cold retention. Coils, fans and fin spacing may be customized to provide optimum performance

Coils, fans and fin spacing may be customized to provide optimum performance

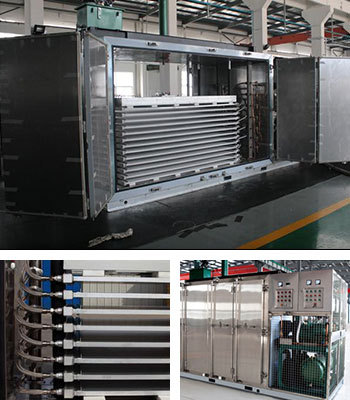

Plate contact freezer

Products:Shrimp, Fillets in Blocks, Vegetables, Fish Blocks and Chopped products

Features:The plate freezer is made with a heavy-duty steel frame and is mounted with hydraulic rams ensuring a stable and even plate pressure blocks. Double contact plate freezing is a fast and economical way of freezing due to double contact with the product packaging. Furthermore, the fast low temperature freezing maintains the natural quality of the product.

Dual modes of Air blast and direct contact guarantee fast freezing. Electric energy vibrates the water molecules inside the freezer, preventing the formation of ice crystals inside the cells. This protects the cell walls from damage, and lessens drip when defrosting. A layer of ice quickly covers the surface of the food, preventing cell moisture from escaping and eliminating frost. The fan air speed changes automatically, preventing surface drying.

Benefits:

All stainless steel cabinet

All stainless steel cabinet Robust and easy to clean

Robust and easy to clean Hydraulic Powered lift and down plates.

Hydraulic Powered lift and down plates. Contact freezing with double Aluminum-alloy plates to assure high freezing capacity.

Contact freezing with double Aluminum-alloy plates to assure high freezing capacity.

- FSW series Tunnel freezer

- FSL series spiral freezer

- FSLD Series IQF freezer

- FIW Series Impingement tunnel freezer

- FIM Series Ice maker machine

- Frozen french fries products line

- Liquid Nitrogen Tunnel Freezer

- Blast Freezer

- Cold Room

- Refrigeration Compressor unit

- Thawing machine

- Vacuum Rapid Cooling Machine

- Industrial Freeze drying machine

- Air Condenser

- Fruit &Vegetable processing machinery

- Blast Freezer

- Blast Freezer

- Blast Freezer

- Blast Freezer

- Blast Freezer

- Name:

- SUNNY SUN

- Tel:

+86-18698104196

+86-022-28577128

- WhatsApp:

- 8618698104196

- Skype:

- 18698104196

- Address:

- Tianjin China